Waste heat is everywhere. Yet most of it still escapes unused.

Through the LIFE4Heat Recovery project, we explored how this overlooked energy source can be transformed into a valuable asset — technically, economically, and environmentally.

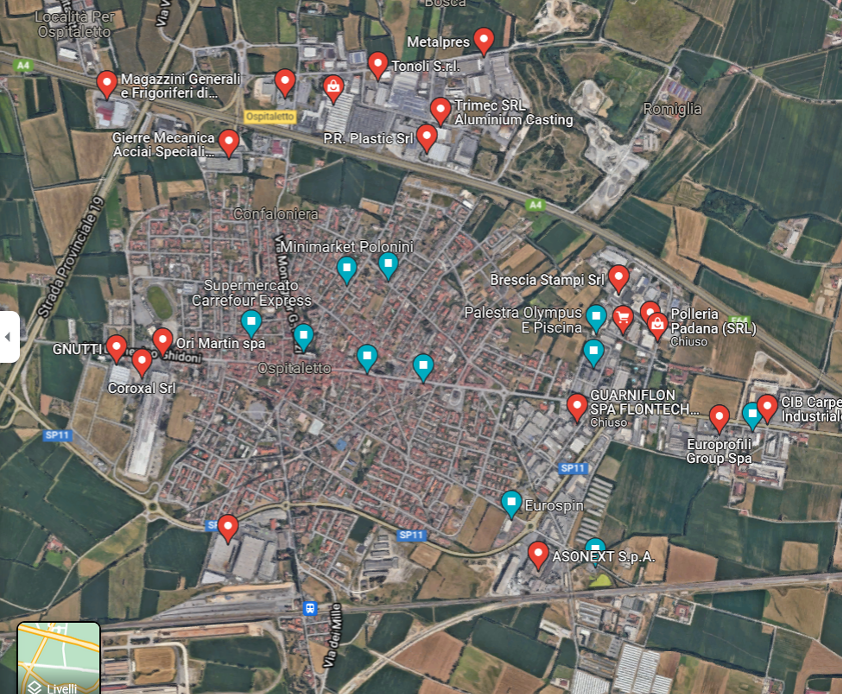

One of the most promising case studies came from Ospitaletto, Italy, where we analyzed the heat recovery from a steel foundry’s cooling system. At a modest 25 °C, this heat would normally be lost — but instead, it was redirected into a cold water network operated by a local energy supplier, and even reused by the foundry itself.

Waste Heat Recovery Potential and Low-Temperature Network

In this project it was demonstrated:

- How low-temperature heat (as low as 15 °C) can still be valuable

- The dual opportunity to feed both district energy systems and in-house heating

- The role of heat pumps in increasing usability (up to 60 °C for space and water heating)

This is just one of several real-world examples we’ve studied. Over the next posts, we’ll go deeper into how the system works, the environmental and financial results, and what it could mean for your business or municipality.

Read the next post

How We Support Your Project

• Pre-Development Site Analysis

We assess potential sites for new developments, evaluating environmental impact, technical feasibility, and energy demand potential.

• Site and Master Planning

We design comprehensive decarbonization and energy transition plans for large-scale developments, campuses, or districts.

• Regulatory & Funding Alignment

We create actionable plans that align with compliance requirements, capital planning needs, and available funding mechanisms.

• Advanced Modeling & Simulation

We apply cutting-edge modeling tools to quickly simulate scenarios and identify high-impact, cost-effective solutions.

The Bigger Picture

Waste heat recovery is one of the most underutilized levers in industrial decarbonization. In heavy industry, where processes often release consistent low- to medium-grade heat, a well-designed district heating network can:

- Cut CO₂ emissions by displacing fossil-fuel-based heating.

- Reduce energy costs through fuel savings and improved process efficiency.

- Create infrastructure value that serves both current operations and future expansions.

Interested in evaluating your heat recovery potential? Get in touch with our team.

One response to “Turning Industrial Waste Heat into Value”

[…] city of Ospitaletto (in the Lombardia region) as a promising case for industrial heat recovery (see Project Overview – Post 1), the technical challenge was clear: how to recover very low-temperature waste heat (~25 °C) and […]